AI-Powered Predictive Maintenance: Transforming Industry Efficiency and Equipment Lifespan

AI for Predictive Maintenance: Revolutionizing Manufacturing and Beyond

Understanding Predictive Maintenance (PDM)

How AI and Data Analytics Enable Predictive Maintenance

Key Components of AI-Driven Predictive Maintenance

Using artificial intelligence-driven predictive maintenance involves a few key components:

Data Collection and Processing

PDM begins with IoT sensors and devices continually monitoring machinery and sending data to central systems. Continuously gathering data on equipment conditions, these sensors detect temperature, pressure, and vibration. Often used for storage and processing this data are cloud-based solutions, which guarantee scalability and simple access for analysis.

Machine Learning Models

Artificial intelligence uses machine learning (ML) algorithms to forecast equipment failure. These algorithms are taught utilizing past data to identify particular trends pointing to possible problems. Anomaly detection models, for example, can highlight anomalies in machine performance or highlighting discrepancies pointing to wear or failure. Especially when tracking equipment with complicated operational patterns, neural networks, and time-series analysis are also somewhat frequently utilized.

Data Analysis and Decision-Making

AI’s true potential is in enabling the analysis to be taken action after the data is analyzed. It produces predictive insights and alarms, therefore enabling maintenance teams to respond proactively. For instance, a maintenance crew can act before the machine fails if artificial intelligence identifies an increase in vibration levels indicating possible bearing wear. Such realizations help flexible, just-in-time treatments instead of depending on scheduled maintenance cycles.

Benefits for Industries like Manufacturing

Predictive maintenance powered by artificial intelligence offers significant advantages in sectors where operational efficiency is a top priority:

- Reduced Downtime: PDM helps reduce unplanned breakdowns by estimating when equipment is most likely to fail. In an industry, where unscheduled downtime may stop lines of production and affect delivery dates, this is vital.

- Cost Savings: Reducing unneeded preventative maintenance schedules and lowering unscheduled repairs helps to minimize maintenance expenses. PDM helps businesses save costs by letting them concentrate resources where they are required. For instance, Airbus said that using predictive maintenance solutions powered by artificial intelligence resulted in a 20% drop in maintenance expenses.

- Extended Equipment Lifespan: AI’s exact observations of equipment condition enable prompt repair based on which wear and tear is prevented from developing into irreversible harm. This preventative maintenance helps machines last longer over time, therefore postponing the need for expensive replacements.

Challenges and Considerations

Data Quality and Quantity: High-quality data is mostly relied upon by artificial intelligence models to provide reliable forecasts. Low-quality or inconsistent data might produce inaccurate forecasts, therefore compromising the efficacy of the system.

Implementation Costs: Setting up AI-powered PDM solutions calls for IoT infrastructure, data storage, and qualified people investments. Though the long-term benefits are significant, smaller businesses may find the early expenses exorbitant.

Skills Gap: AAI-driven PDM depends on knowledgeable staff to manage, understand, and polish data insights. Businesses might have to make training investments, recruit experts, or explore outsourcing predictive AI projects to providers with established expertise to make good use of the data AI offers.

Conclusion

Predictive maintenance will get even more advanced as artificial intelligence develops and provides quicker, more accurate insights. Organizations that lack in-house AI expertise can consider outsourcing predictive AI development and implementation to specialized partners to accelerate adoption. Looking ahead, artificial intelligence’s influence on maintenance and asset management will only become more apparent; maybe a day when operations run at perfect efficiency, maintenance is completely predictive, and equipment failure is a thing of the past.

How LLMs Are Revolutionizing Text Mining and Data Extraction from Unstructured Data

How Businesses Use LLMs for Competitive Intelligence to Stay Ahead of the Curve

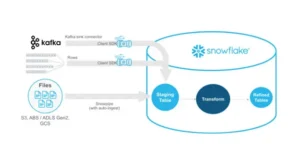

Maximizing Cost-Efficient Performance: Best Practices for Scaling Data Warehouses in Snowflake

Implementing Snowflake Data Governance for Scalable Data Security